Dal Mill Machine Online Collection, Save 67 jlcatj.gob.mx

The accuracy of a milling machine can vary widely depending on the machine design, component (particularly slide) quality, and the operator. For many standard milling machines, positional accuracy can range from a few thou (0.001" or 0.0254 mm) to a few ten-thousandths of an inch (0.0001" or 0.00254 mm).

What Are The Types Of Milling Machine TAICNC

New milling machine technology allows you to achieve tighter tolerances, maintain high production rates and avoid placing new demands on the milling crew. "The newer generation of grade controls.

Conventional Machining MechanicsTips

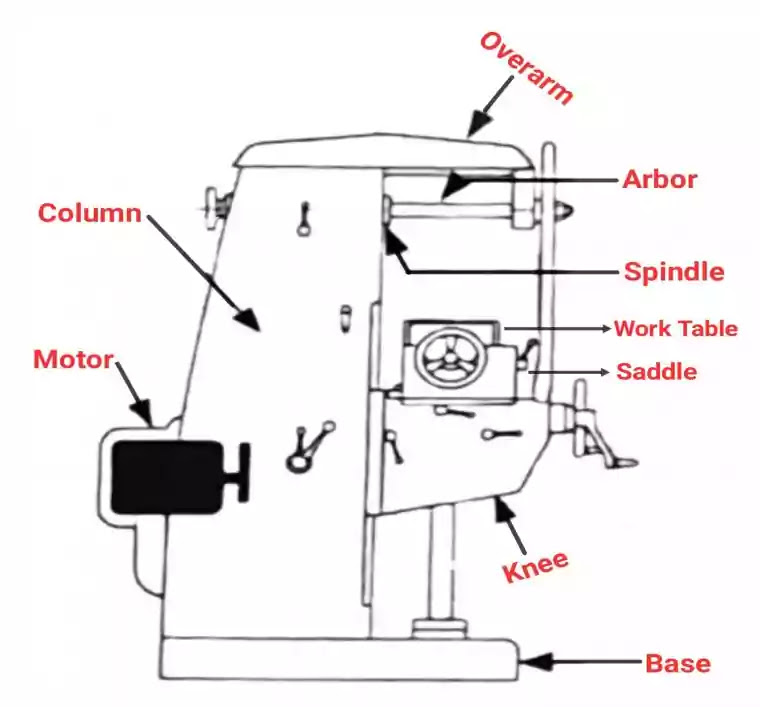

MILLING OPERATIONS Milling is the process of machining flat, curved, orMilling machines are basically classified as vertical or irregular surfaces by feeding the workpiece against a rotating horizontal. These machines are also classified as knee-type, cutter containing a number of cutting edges.

How to Design for CNC Milling

LabelMill 55 Gallon Drum Label Applicator - Full Color Print & Apply GHS Compliant Trap & Wrap LABEL APPLICATION - FAST & EASY From Concept to Final Product our Modular Labeling Systems are Quick to Deliver - Easy to Service - Easy to Use That means… More Uptime for Your Lines

Warco HV Horizontal Vertical Milling Machine Universal Industrial Mill

Label Mill offers a range of label applicators and print and apply labeling applicators. With all applications being flexible, they can be easily integrated into current production lines.

Baileigh Industrial Vertical Mill Variable Speed Milling Machine Baileigh Industrial

Ancillary Equipment. Label Mill Print & Apply Labeler. LabelMill LM3612 Print & Apply Tamp Labeler is "brand new, in crate". Configured for rotary premade pouch fill & seal machine. Include McLane mounting brackets. Adjustable product delay, tamp duration, flag duration and label speed. Hand-held user interface.

Understanding CNC Milling

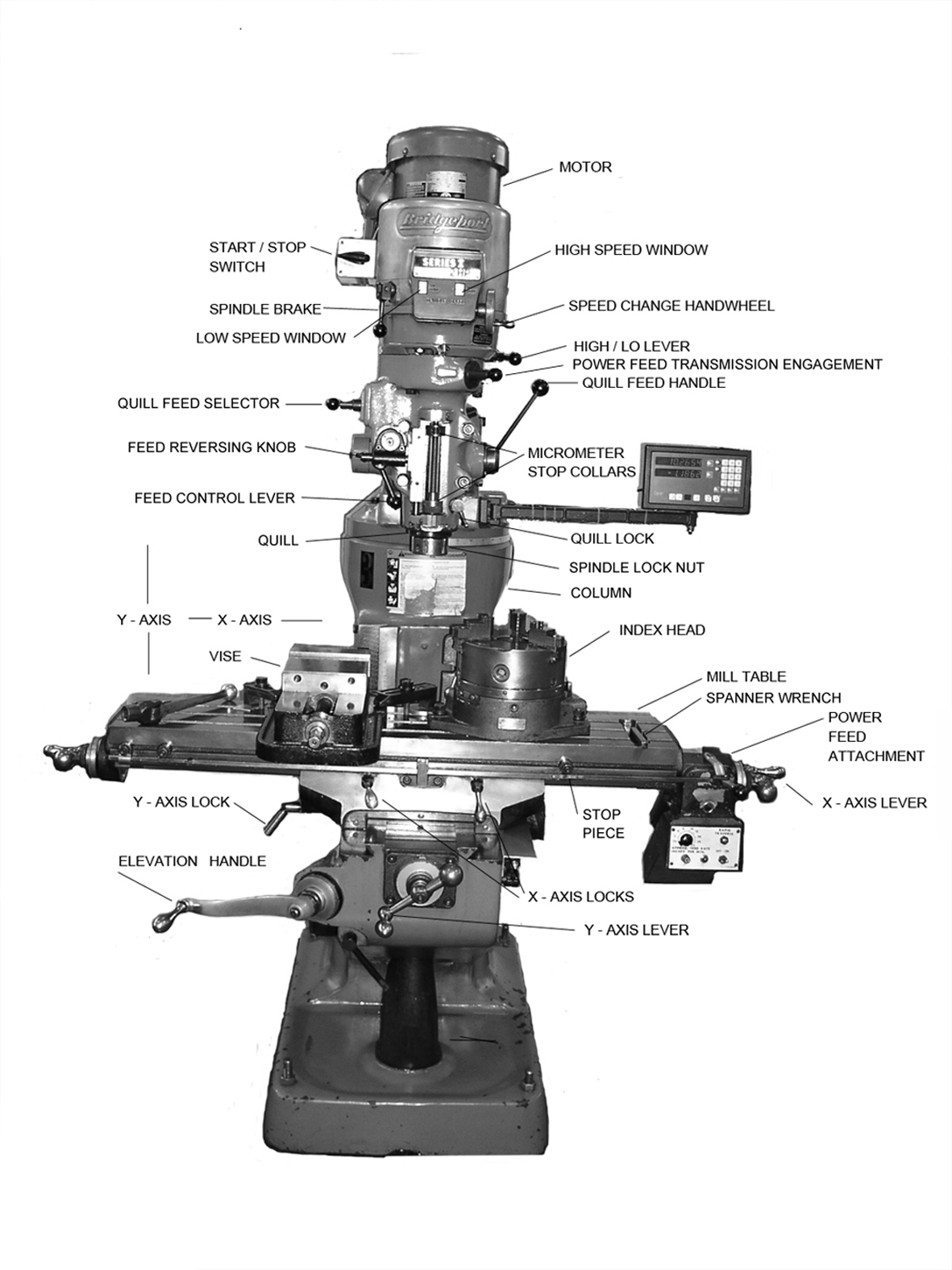

Milling (machining) A 3-axis clone of a Bridgeport -style vertical milling machine Milling is the process of machining using rotary cutters to remove material [1] by advancing a cutter into a workpiece. This may be done by varying directions [2] on one or several axes, cutter head speed, and pressure. [3]

CNC Milling a Complete Guide to Understand the Process

Product Labeling Machine for Quality Control Manufacturing Why A Product Labeling Machine Is Essential for Quality Control in Manufacturing In the realm of manufacturing, every product goes through stages before it is ready for the market. Among these stages, labeling stands out as one.

Milling Machine Terminology Sherline Products

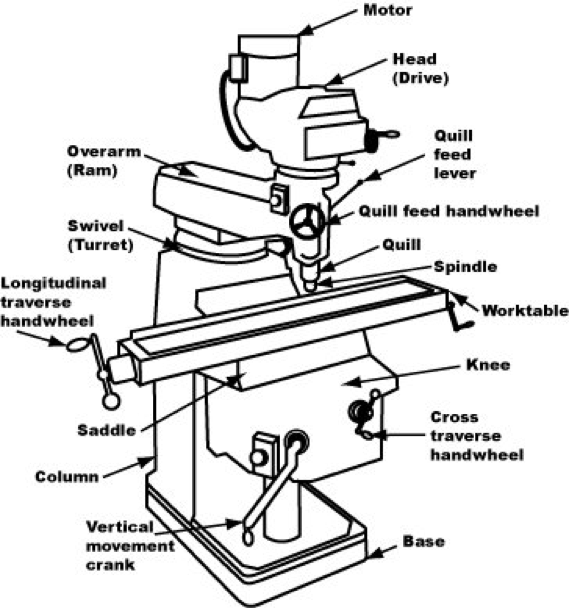

The vertical milling machine is a 3-axis milling machine. It has a table acting as a work surface and spindle. In vertical milling machines, as the name suggests, the spindle axis has a vertical orientation. The cutters rotate on its axis held by the spindle. The vertical CNC milling machines are further classified into two groups,

Professional Quality Free Delivery & Gift Wrapping free shipping 2VSG COMET 2SG 3VHG 4VHG

CONTACT US NOW! Semi-Automatic Table-Top Label Applicator Explore top-of-the-line table top applicators from LabelMill for effortless labeling solutions. Enhance efficiency and accuracy in your labeling process.

The wandering axeman Selecting and buying a metal milling machine for the hobbyist

Modular Labeling Machinery. All Pack Leader USA labeling machines are constructed of stainless steel, anodized aluminum and synchronized controls. This impressive combination provides the best labeling solution for your business. Pack Leader USA labeling systems are easy to set up, easy to maintain and most importantly, easy to operate.

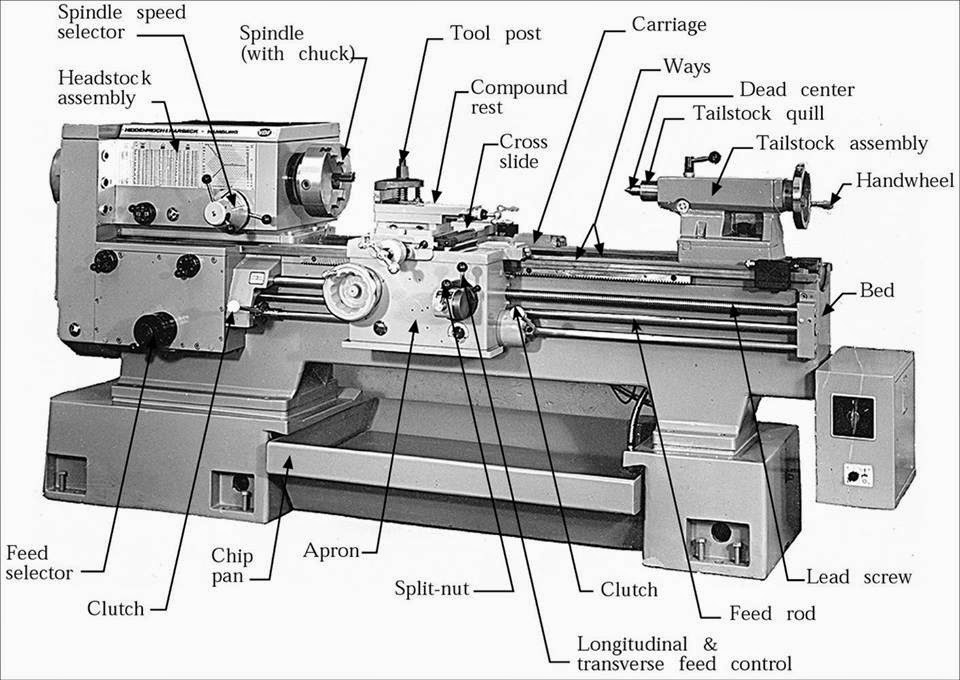

Mechanical Engineering Detailed part identification and terminology of Lathe Machine

The LabelMill 1512 is a high-speed applicator that comes standard with features normally found on high end custom systems. Features such as 2 dozen I/O points for easy integration into your application. Download the Brochure Download the Manual FAQs Contact us Today for a Free Consultation USE CASES Easy integration to scales Bar-code scanners

The Fundamentals of a Vertical Machining Center (VMC)

A milling machine is a piece of equipment that removes a layer of material from the surface by using a multi-point cutting tool. With the aid of numerous cutting edges, the milling cutter revolves at high speed while rapidly removing metal. Cutters can be mounted simultaneously in groups.

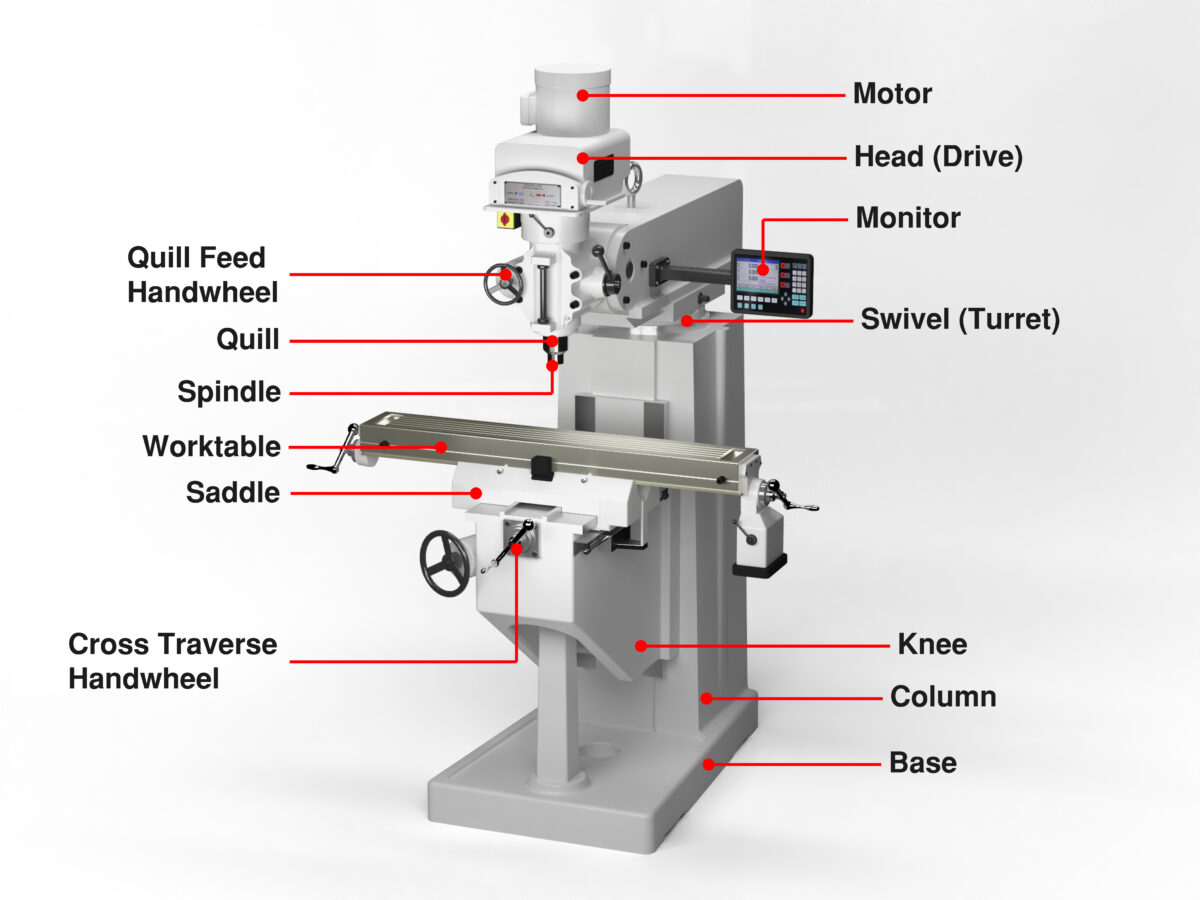

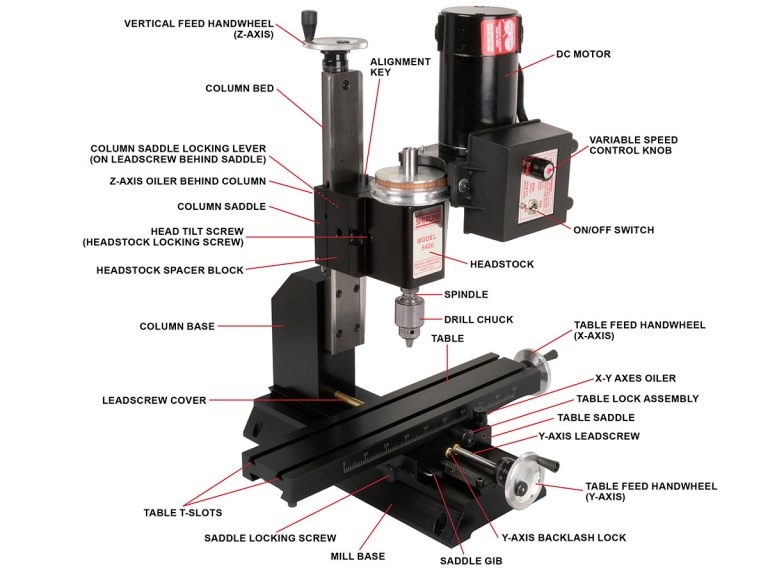

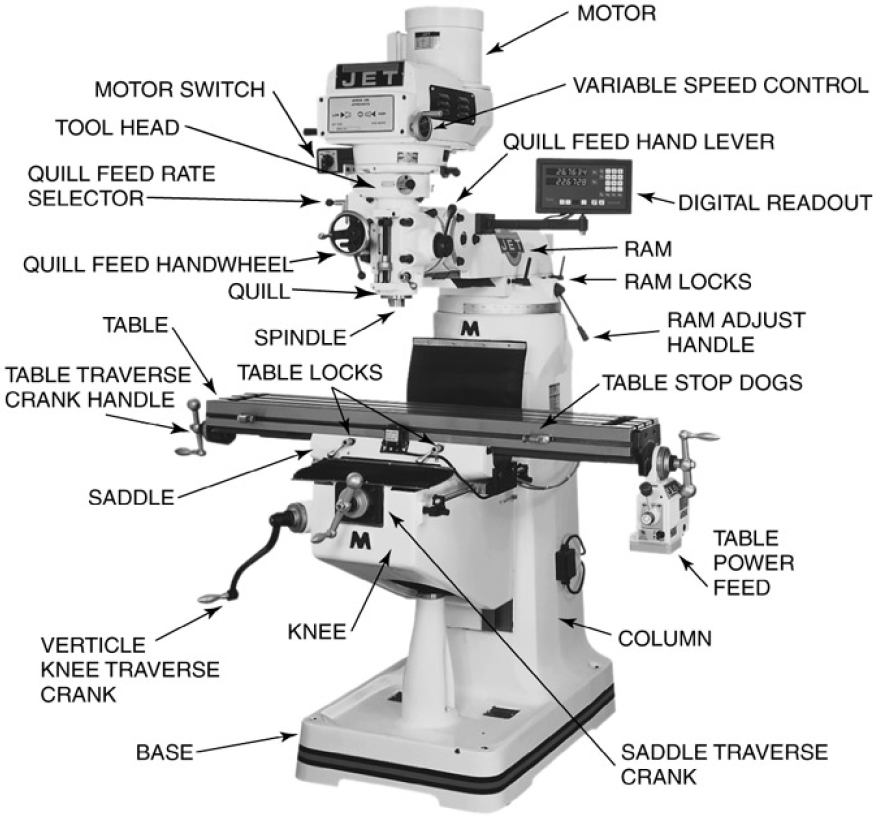

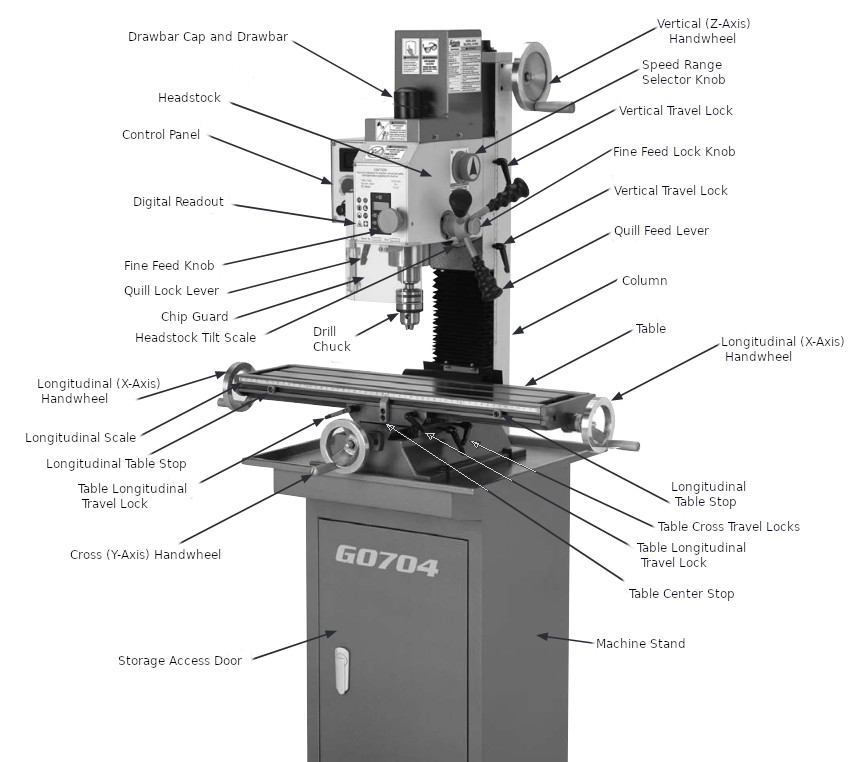

Milling Parts Identification

Types of Milling Machine [Complete Guide] :- Milling machines are used for the removal of metal piece with the help of a rotating cutter, and the cutter rotates at very high speed for efficient removal of metal piece. Rotating cutter has cutting edges which help in cutting materials. Milling machines are capable of holding one or more cutter at.

Milling Machine Parts and their Function hubpages

Milling is the machining process in which the removal of metal takes place due to the cutting action of a rotating milling cutter. In a milling machine, the cutter is rotating due to workpiece is fed against it. This machine can hold more than one tool at a time.

Lathe & Mill Nomenclature

Every label reflects your company's brand image. A label that is crooked or placed incorrectly might appear insignificant. It can give the impression of carelessness to customers, raising doubts about the quality of the product. Consistency: Labeling machines ensure that each product is labeled in a way maintaining a brand image. Professionalism: